In a symphony orchestra, all instruments, from violins to timpani, play in perfect harmony under the guidance of a skilled conductor. That’s the role TGW Logistics’ warehouse management system, WERX, plays in modern warehouses—a centralized system orchestrating all processes from inbound to outbound to ensure peak efficiency, precision, and scalability. With WERX warehouse management software at the helm, warehouses operate seamlessly and are ready to handle complex challenges across all industries.

What’s in the Orchestra: Components of WERX Warehouse Management Software

The WERX software suite combines related functions and features into three areas to achieve common goals within the warehouse:

This houses all operational functions and is divided into the sections Warehouse Orchestration, Warehouse Execution and Mechatronic Management. Together, these components form a comprehensive approach to modern warehouse management, integrating both human and automated resources to maximize efficiency and productivity.

- Warehouse Orchestration: Acts as the conductor, providing holistic management and coordination of all processes, systems, and resources within a warehouse.

- Warehouse Execution: Handles day-to-day tasks and processes to stay on track and meet efficiency goals.

- Automation Management: Oversees and controls the warehouse's mechanical, electronic, and computer-based systems. It manages hardware and software components that drive automation and robotics in modern warehouse environments.

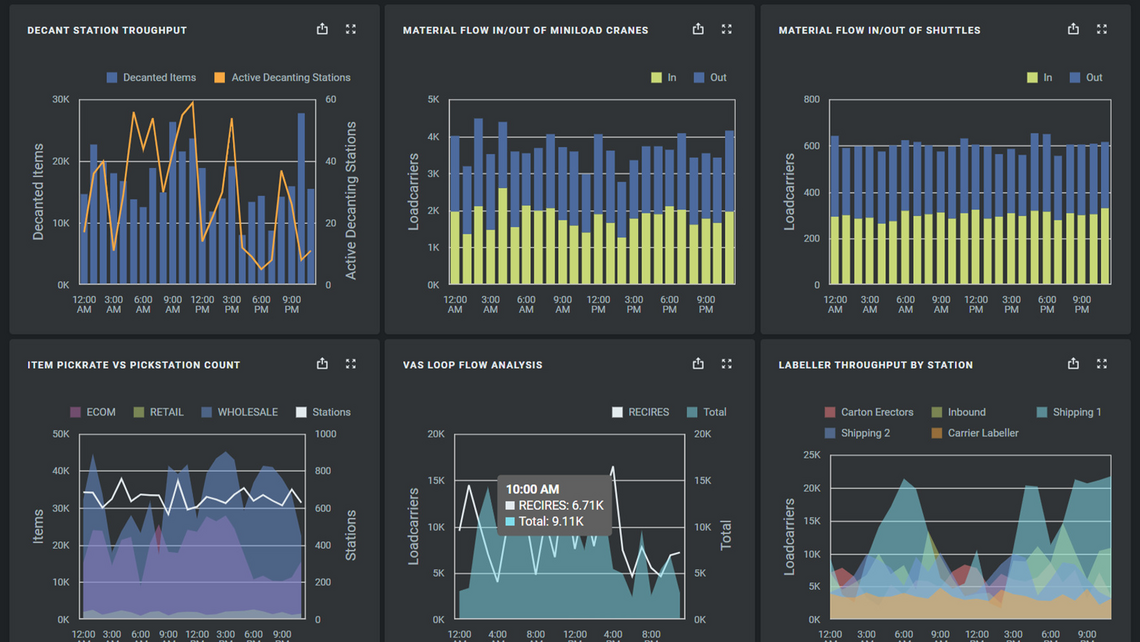

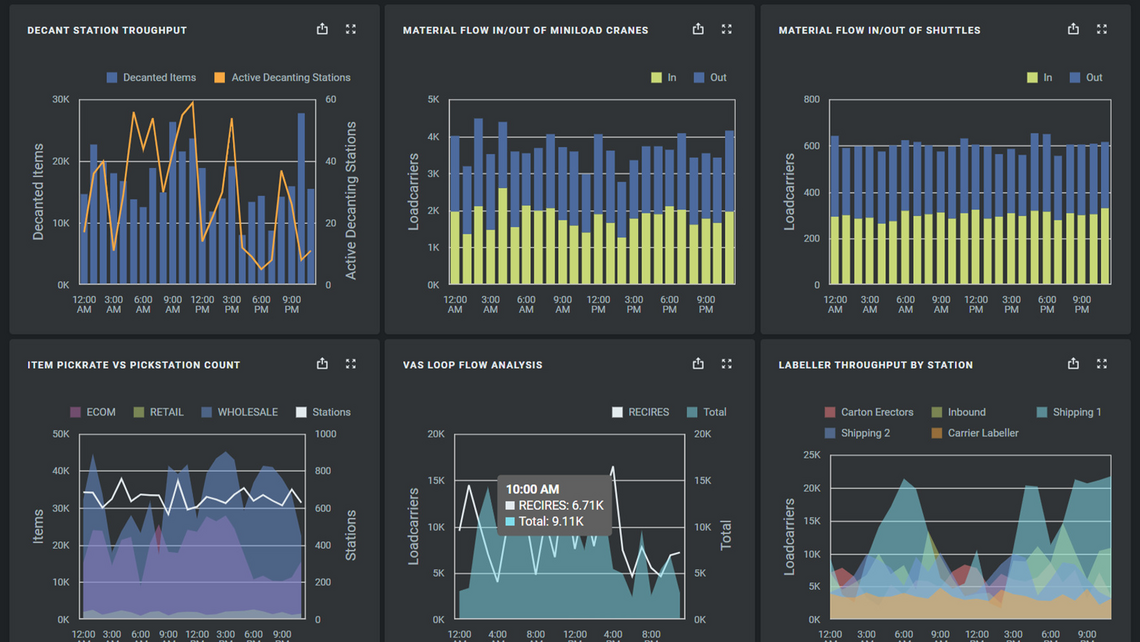

The Analytics module offers a range of analytics products and provides real-time data insights, offering businesses the transparency they need to make proactive, data-driven decisions. By delivering actionable intelligence, WERX Analytics allows companies to refine workflows, anticipate challenges, and improve operational efficiency.

WERX Services provides system stability and long-term efficiency through comprehensive support. From maintenance to troubleshooting, this component guarantees that all WERX software products deliver consistent value over time.

WERX Products

The suite includes different key products, each designed to address specific logistics needs:

- WERX Warehouse Management: Designed to optimize and manage the daily operations of a warehouse.

- WERX Material Flow: Coordinates flow of load carriers and materials in automated warehouses for smoother operations.

- WERX Mobile Robotics: Serves as the central brain of the robotic fleet, efficiently assigning tasks, optimizing routes, managing traffic, and ensuring seamless integration with other warehouse management systems to maximize productivity and minimize conflicts or bottlenecks.

- WERX SAV: Provides acquisition, control, and visualization of real-time data of mechatronic equipment on-site.

- WERX Portal: Contains the UI/UX Design, tools, technologies, and security practices to provide a single window into TGW Logistics WERX applications, whether installed on-site or live in the cloud.

Together, these components and products form a comprehensive, modular solution. Just like an orchestra relies on each instrument to contribute to the symphony, WERX brings together every part of your logistics operation to work in perfect harmony.

Coordination Across Complex Logistics

By coordinating automation tools like the TGW Logistics Stingray Shuttle System and ergonomic goods-to-person picking stations, our software streamlined workflows, reduced errors, and enhanced employee productivity. The automation solution handles up to 1,600 totes per hour, eliminating inefficiencies like long walking distances and manual handling.

Our software merges human and robotic tasks, enabling retailers to meet high-volume demands with precision and reliability. The ability to orchestrate diverse processes highlights our unparalleled capacity to drive operational excellence across industries.

Scalability and Flexibility Across Industries

One of WERX’s standout features is its modular design, which allows businesses to tailor their logistics systems to current needs while scaling effortlessly as those needs evolve. Much like a conductor adapts to different compositions, leading a small chamber orchestra or a full symphony with equal precision, WERX aligns every “instrument” in the logistics system to play in harmony, no matter the scale or complexity of the operation.

By integrating modular components like the Stingray shuttle system and FlashPick goods-to-person workstations, warehouses can streamline their picking processes across wholesale, retail, and direct consumer channels. This modular approach improves order accuracy, reduces operational bottlenecks, and seamlessly adapts to fluctuating demands, all without requiring a complete logistics overhaul.

Comprehensive Data and Analytics with WERX

With WERX Analytics, businesses can make proactive, data-driven decisions based on real-time insights and complete transparency into their operations. Just as a conductor relies on precise cues to guide the orchestra, WERX offers detailed performance metrics that validate every process runs in perfect synchronization. Current data and analytics allow for proactive decision-making, which optimizes order processing through advanced data insights. This enables process transparency, empowering companies to refine their operations based on detailed performance metrics.

Efficiency Through Advanced Automation Management

WERX’s advanced automation capabilities redefine efficiency, enabling warehouses to meet increasing demands with precision and speed. By minimizing manual interventions and streamlining workflows, WERX supports high-throughput environments while reducing errors.

A Warehouse Management System That’s In Sync

A series of integrated modular software components enrich the core platform. Based on the principle of distributed intelligence, our components provide standardized, autonomous support for the required business processes and sub-processes. Our proven components, which are developed and maintained in conjunction with automated equipment at the module, system and robot/machine level, can be used individually or integrated into broader applications as part of our platform. Granular scaling is made possible by a stringent, structured approach to APIs, data management, monitoring, and software deployment. Our scaling model represents an industry-leading approach that offers the flexibility to gradually add technologies, functions, features, and improvements without impacting the core platform.

WERX's intuitive user interface enables users to work quickly and efficiently, reducing onboarding time and minimizing training costs. Another advantage is deep integration and connectivity. The software supports integration with a variety of existing ERP systems, machines, and devices, facilitating data exchange within the company and with external partners. This results in seamless connectivity and real-time transparency, enabling companies to make faster, more informed decisions and respond proactively to challenges.

WERX supports a high level of process automation, leading to increased efficiency and reduced errors. The software enables manual interventions to be minimized through automated workflows and notifications. To make the full potential of the software available to our users, TGW Logistics offers extensive customer support and training opportunities for the WERX software suite. More than 750 digital experts are passionate about developing our WMS software and digital solutions for customers worldwide.

TGW Logistics is a foundation-owned company headquartered in Austria and a global leader in warehouse automation and warehouse logistics. As a trusted systems integrator with more than 50 years of experience, we deliver end-to-end services: designing, implementing, and maintaining fulfillment centers powered by mechatronics, robotics, and advanced software solutions. With over 4,500 employees spanning Europe, Asia, and North America, we combine expertise, innovation, and a customer-centric dedication to help keep your business growing. With TGW Logistics, it's possible to transform your warehouse logistics into a competitive advantage.