- Reduced throughput times, improved picking performance, increased efficiency

- Kerbl and TGW Logistics have built a longstanding partnership based on mutual trust

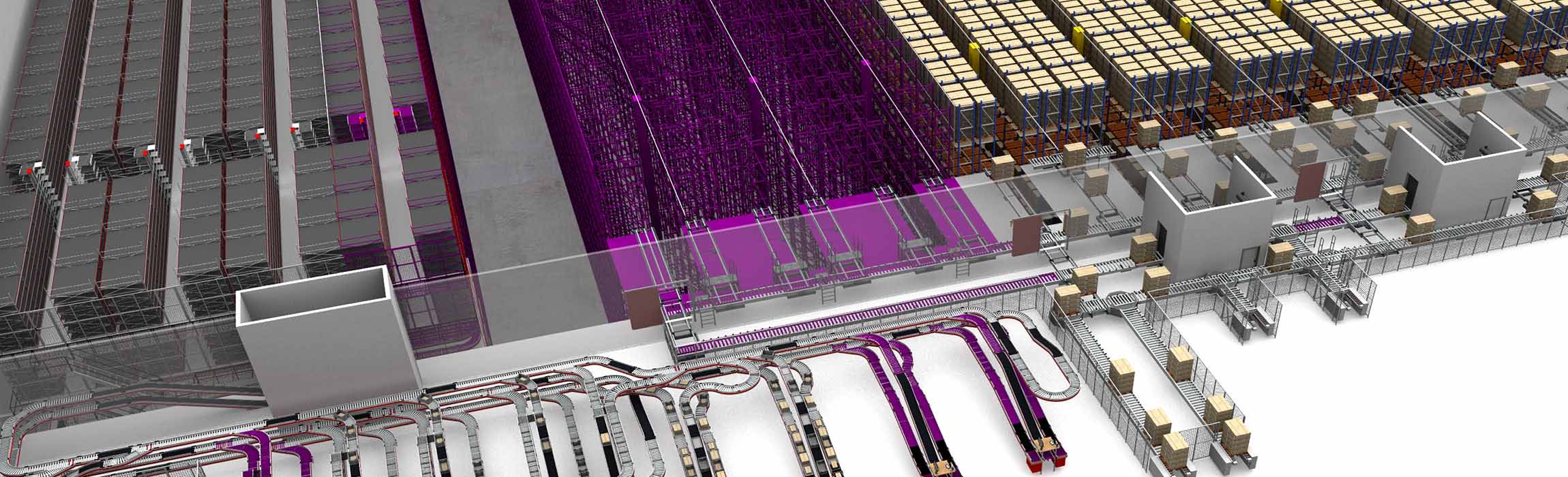

- The centerpiece of the TGW solution consists of a shuttle system with ergonomic picking workstations and a pallet high-bay warehouse for increased capacity

(Marchtrenk, Austria, 2 April 2024) Albert Kerbl GmbH's fulfillment center in the municipality of Ampfing, Germany is undergoing an expansion that is expected to be finished by October 2025. The family-owned company, which produces and sells products for the keeping and breeding of animals, is putting its trust in the experience and expertise of TGW Logistics for this project.

Albert Kerbl GmbH was founded 40 years ago in Buchbach; what began as a small agricultural business with five employees in 1984 has now grown to become an internationally active company with locations in Germany, Austria, Poland, France, and Great Britain. Kerbl has specialized in the areas of agricultural supplies, fencing, protective equipment, horse and rider, hobby farming, and pets, and employs more than 700 people.

Longstanding collaboration

The animal breeding and husbandry specialist is banking on automation - and on collaboration with TGW Logistics - to be able to continue offering their customers an optimal service level, significantly reduce order throughput times, and increase efficiency.

"We have a strong bond with Albert Kerbl thanks to our longstanding partnership. We are delighted that the customer is once again relying on the expertise and experience of TGW Logistics for the expansion of their fulfillment center: that is a great vote of confidence," points out Thomas Berndorfer, CFO Central Europe at TGW Logistics. "Together, we are setting out on the next stage of the automation journey."

"We are very happy to announce the signing of the contract with TGW Logistics! This collaboration builds on an existing partnership based on great trust," says Maximilian Leinfelder, Project Manager at Albert Kerbl. "We have come to know TGW Logistics as an extraordinarily solution-oriented and goal-driven company. Their professionalism and commitment have left a long-term impression on us and leave us feeling optimistic about the successful coordination of this project over the coming years."

High-performance goods-to-person picking

The centerpiece of the FlashPick® system consists of a three-aisle shuttle warehouse with 90,000 storage locations, an automatic pallet high-bay warehouse, and ergonomic PickCenter One picking workstations. The different areas of the installation will be connected by energy-efficient KingDrive® conveyors, and all processes will be controlled and monitored by TGW Warehouse Software. Automation will not only enable shorter order throughput times and increase efficiency, but also provide an answer to the shortage of labor.