- High-performance order fulfillment system 'FlashPick®' system lays the foundation for the planned growth

- Efficient, future-proof omni-channel solution

- PickCenter Rovolution: robot-based high-performance picking

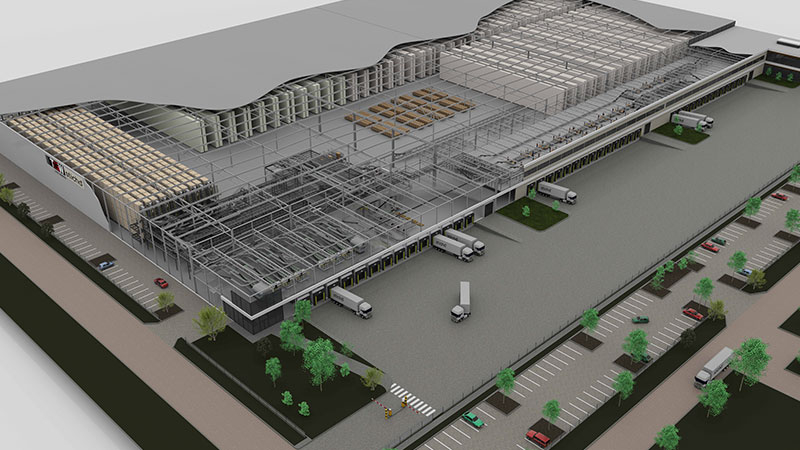

(Marchtrenk, Austria, 25 February 2021) TGW is implementing a highly automated fulfillment center for stichd in Tilburg, The Netherlands, which is slated for completion in November 2022. The omni-channel solution, which is high-performing and extremely versatile at the same time, enables the fashion company to cut lead times and to offer its customers an even higher service level.

stichd -part of the PUMA Group - specializes in the design, production and distribution of high-quality bodywear, legwear, and swimwear. The fashion company also designs, develops and distributes licensed fanwear, collaborating with top racing Formula 1 teams amongst others.

Future-proof Fulfillment processes

To lay the foundation for the planned growth and to further enhance the efficiency of the processes, stichd relies on a high-performance omni-channel solution by TGW. Nina Nix, CEO of stichd, emphasises, ‘Implementing the TGW solution is a next step in our journey to making stichd fulfilment processes future-proof.’

FlashPick® as centerpiece

The centerpiece of the end-to-end solution is TGW’s order fulfilment system 'FlashPick®' which allows for serving various sales channels with equal efficiency – eCommerce, wholesale and retail. It comprises a five-aisle shuttle warehouse with 20 levels, six PickCenter One picking workstations as well as two robot-based PickCenter Rovolution. The TGW Warehouse Software manages all processes. The 2.5 miles KingDrive® conveyor system ensures energy-efficient transport of goods.

Cartons delivered at goods receipt will be transported to the pallet reserve warehouse that is used for replenishing FlashPick®. Wholesale or retail orders are picked directly into shipping cartons. Customer orders can then be delivered to the VAS (value added service) workstations where additional enclosures might be added if necessary.

Possible extension as early as 2025

The solution can easily be expanded by doubling the shuttle system and the connected picking area. If stichd continues to grow as dynamically as predicted, the extension could be planned as early as 2025.