Leroy Merlin

& TGW Logistics

乐华梅兰的消费品物流变革之旅

高级自动化与仓库人体工程学

作为法国家装和室内设计市场的领军品牌,乐华梅兰(Leroy Merlin)面临着来自旗下门店和直接客户不断增长的需求。面对复杂的产品线以及对高效订单履行的迫切需求,Leroy Merlin选择与TGW物流合作,在巴黎附近打造全新的订单履行中心。凭借TGW物流先进的自动化技术和优化的仓库人体工学设计,曾经看似难以解决的物流难题如今已转化为高效的运营流程。

化挑战为机遇:征程开启

乐华梅兰认识到,其现有的履行流程已难以适应现代消费品物流的快速发展:

- 劳动力短缺和繁重的人工流程,导致效率低下。

- 产品笨重、种类繁多且复杂,给仓库员工带来沉重的负担。

- 公司亟需提升交付速度、降低成本,同时保障员工工作场所的健康安全。

TGW物流量身定制的自动化和供应链优化方案,将直击这些痛点。

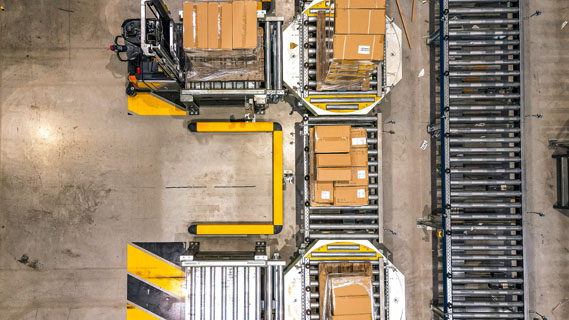

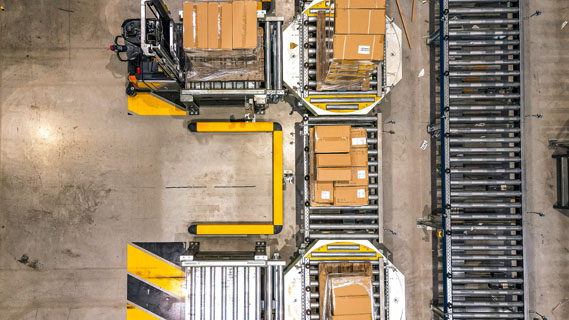

高效的KingDrive输送系统连接各个功能区域,确保货物在存储区和拣选站之间顺畅流转,实现了消费品物流的高效运作。六个零差错的1:1高性能拣选工作站(一个订单箱对应一个源箱)确保了零售订单的高效、精准履行。我们的WCS仓库控制系统全程把控整个操作流程,从规划到监控,确保系统达到最佳性能。

在新系统上线之前,由于产品尺寸多样,尤其是重型物品,人工码垛工作难度大。如今,结合自动化货到人拣选和AGV智能小车,流程得以简化,团队能高效处理最具挑战性的产品。

自动化与人体工程学:员工的福音

自动化拣选区还设有半自动拆垛工作站,可借助AGV从收货区和仓库实现自动补货。在人体工程学方面,我们对每个人工工作站运用RULA方法进行了细致分析与优化,有效降低了员工肌肉骨骼损伤的风险。乐华梅兰选用了半自动化的SlotStax码垛方案,并配备机器人来处理料箱中的重型及笨重物品。考虑到不同门店所需码垛产品的多样性,SlotStax解决方案的灵活性显得尤为关键。

这种新的布局让繁重的人工作业成为过去,简化了拆垛流程,同时助力乐华梅兰将完好无损、规整有序的托盘货物顺利送达各门店。人体工程学与自动化水平的提升,使工作环境变得更加安全、更具吸引力,也使乐华梅兰在传统男性主导的行业中,成功吸引了众多女性员工,迈出了意义非凡的一步。此外,通过减轻员工的体力负担,公司有效应对了劳动力短缺难题,留住了多元且高效的优秀团队。

结果:当可能成为现实

在乐华梅兰,速度、成本效益与员工福祉的平衡已成为新常态。其配送中心的转型升级,成功解决了供应链物流难题,全面革新了运营模式,成效显著:

TGW物流的FlashPick系统不仅满足了乐华梅兰的当前需求,更为其未来的运营筑牢根基。如今,配送中心已具备应对日益增长需求的能力,无论是单件订单还是门店的大宗货物订单都能轻松应对。在TGW物流售后服务维护合同的保驾护航下,乐华梅兰可确保系统的持续高可用性,从而有效控制运营成本,保障未来数年的稳定高效运行。这一项目也受到了业界的广泛关注。2023年,该配送中心凭借其在物流和供应链优化方面的创新实践,荣获了极具声望的“供应链之王大奖”(Grand Prix des Rois de la Supply Chain)。

携手TGW物流,一切皆有可能:让我们助您实现愿景

怀揣“无惧任何挑战”的共同信念,乐华梅兰与TGW物流强强联合,将复杂的物流难题转化为高效的消费品物流,打造出更优质的工作环境,并为行业内的配送中心树立了全新标杆。凭借我们的创新解决方案与专业能力,曾经遥不可及的目标,如今已近在咫尺,为全球企业带来可能。

联系我们

Erich Schlenkrich

Vice President Business Development Industrial & Consumer Goods