English

- Stingray HG (hanging goods) shuttle wins in the categories of innovation, high quality and functionality

- TGW further expands expertise in the fashion area

- First customer system has already gone live with the new technology

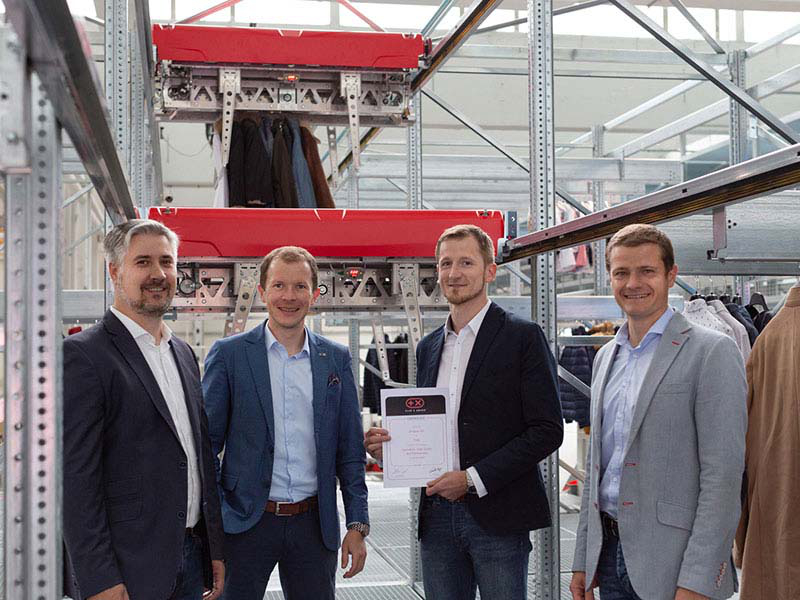

(Marchtrenk, Austria, June 22, 2020) The Plus X Award is the world's premier innovation award for technology, sport and lifestyle. An expert jury selects the winning companies from among those whose products feature exceptional, pioneering quality and innovation. TGW is proud to have received an award for its shuttle system for hanging goods – in the categories of innovation, high quality and functionality.

“The Plus X Award for the Stingray HG underscores the importance of innovations at TGW. We couldn't be happier about the award. It is a wonderful acknowledgement of the development work we have put in in recent months,” says Markus Sturm, CEO of TGW Mechanics. “With this innovation, we are further expanding our expertise in the fashion area. The innovation fits seamlessly into the TGW solution portfolio and provides answers to the challenges of e-commerce and omni-channel business models.”

High throughput and storage density

Handling hanging goods (e.g. suits, dresses or coats) – particularly in combination with goods stored flat – is one of the biggest challenges in fashion logistics. Many companies supply stores as well as wholesale and fulfil online orders to boot. Storing and picking hanging goods efficiently in these types of omni-channel business models requires flexible solutions.

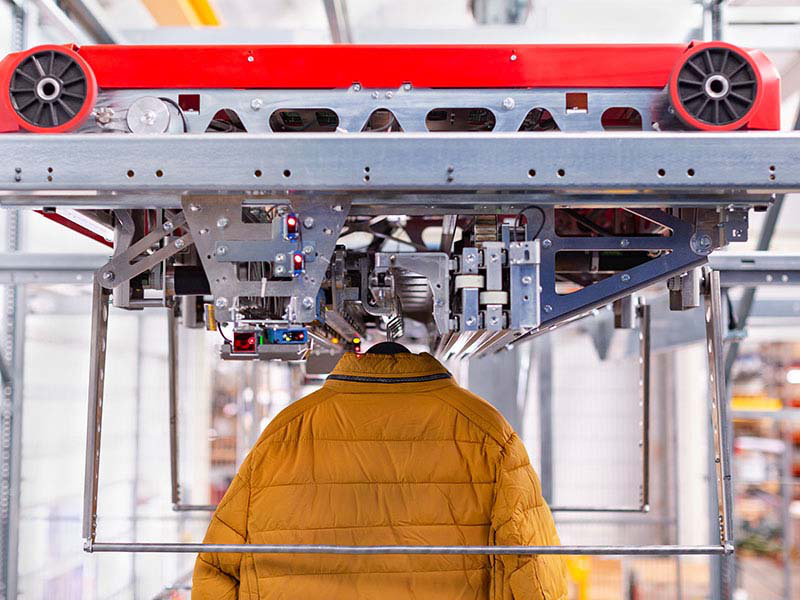

The TGW Stingray HG is a shuttle system for hanging goods that features outstanding high throughput, storage density and easy maintenance. This makes it a high-performance alternative to the storage and retrieval machines frequently in use to date.

Up to 60 percent higher system performance

Conventional clothes hangers are sufficient for hanging the clothes. No additional load carriers are required. The positioning system is accurate to the millimetre, enabling it to be docked on shelves up to 30 metres in height without any gaps. This ensures that the clothes hangers slide smoothly onto the shuttle.

“Twenty years ago, TGW set a milestone in direct handling of cartons and totes with the Twister load handling device for storage and retrieval machines. This likewise pointed the way for the development of the Stingray HG. The clothes hangers should be stored without having a detour caused by additional garment rods,” explains Thomas Gruber, Director Product Management at TGW.

First system goes live

The garments are transported in blocks with a maximum length of 1.2 metres and weighing up to 60 kilogrammes. Storage in the rack is longitudinal relative to the travel direction, not transverse to it as is usually the case for storage and retrieval machines. This allows the available space to be used optimally. Compared to a storage and retrieval machine, the Stingray HG attains up to 60 percent higher system output. The innovative technology also features clever energy recovery, easy maintenance and an intelligent access concept.

“The first system to use the Stingray HG shuttle is already in productive operation at a fashion customer's facility. It is currently in the start-up and acceptance phase,” says Sturm. “Another milestone for TGW in the fashion industry.”